The Basics of Injection Molding: 2020 Guide

Injection molding is a manufacturing process used to produce high volumes of molded parts. The process involves heating material—typically plastic or metal—to a fluid state and injecting it into pre-made molds. The high pressure of the injection operation forces the material to fill every cavity of the molds. Once the material cools and hardens, it retains the shape of the molds even when removed. The molded pieces can then proceed to further processing operations if needed.

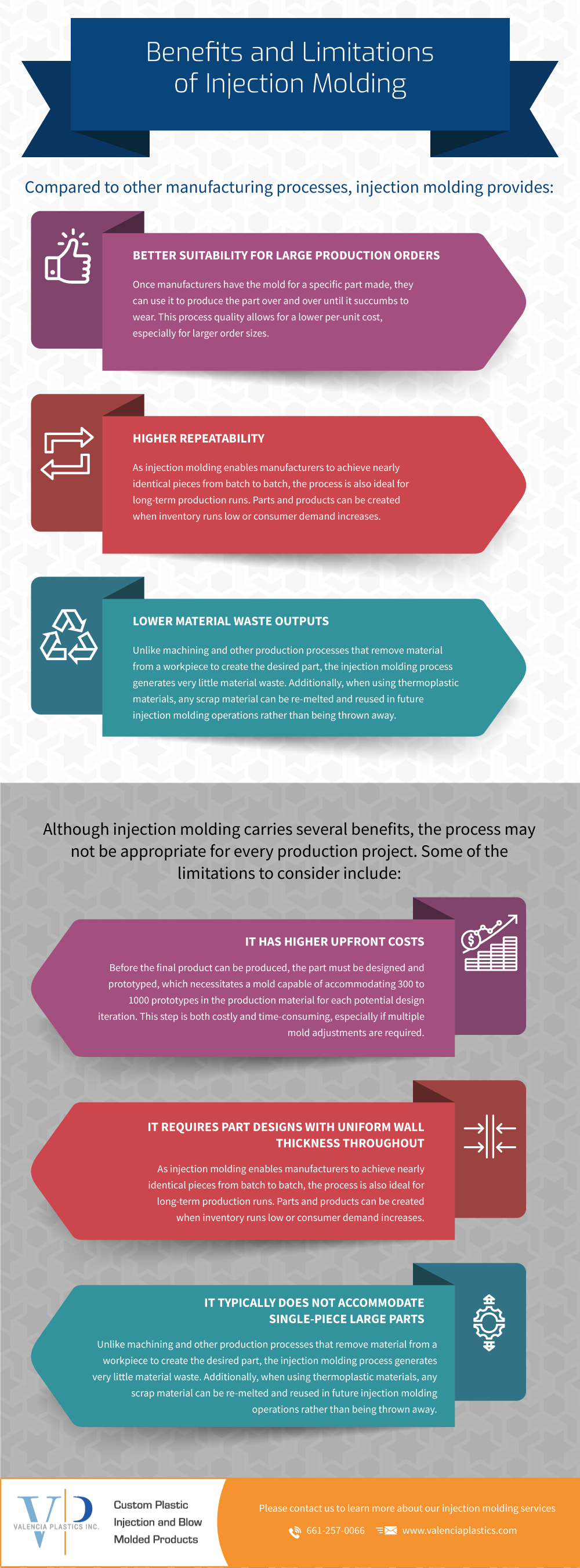

The injection molding process offers many manufacturing advantages that make it suitable for the production of a variety of parts and products, ranging from simple to highly complex. However, there are some drawbacks to keep in mind when deciding on using injection molding for a production run.

The following article provides an overview of the injection molding process, outlining the benefits and limitations, how to calculate clamping force, how injection molding tooling works, and other process considerations.

Benefits of Injection Molding

Compared to other manufacturing processes, injection molding provides:

- Better suitability for large production orders. Once manufacturers have the mold for a specific part made, they can use it to produce the part over and over until it succumbs to wear. This process quality allows for a lower per-unit cost, especially for larger order sizes.

- Higher repeatability. As injection molding enables manufacturers to achieve nearly identical pieces from batch to batch, the process is also ideal for long-term production runs. Parts and products can be created when inventory runs low or consumer demand increases.

- Lower material waste outputs. Unlike machining and other production processes that remove material from a workpiece to create the desired part, the injection molding process generates very little material waste. Additionally, when using thermoplastic materials, any scrap material can be re-melted and reused in future injection molding operations rather than being thrown away.

Limitations of Injection Molding

Although injection molding carries several benefits, the process may not be appropriate for every production project. Some of the limitations to consider include:

- It has higher upfront costs. Before the final product can be produced, the part must be designed and prototyped, which necessitates a mold capable of accommodating 300 to 1000 prototypes in the production material for each potential design iteration. This step is both costly and time-consuming, especially if multiple mold adjustments are required.

- It requires part designs with uniform wall thickness throughout. Both too thin and too thin walls can affect the quality of the finished product. Too thin walls can prevent material from filling the mold completely (especially if the production material is not suitable for thin walls), while too thick walls can cause inconsistencies during cooling.

- It typically does not accommodate single-piece large parts. Molds that are too large run the risk of not being sufficiently pressurized to force the molten material into every section of the mold. Instead, manufacturers create separate molds for individual components and assemble them later.

How to Calculate Clamping Force for Injection Molding Operations

During mold filling operations, injection molding machines employ clamping units to hold the molds closed. The clamping unit must generate enough clamping force to counteract the injection pressure. If the clamping force is insufficient, the mold may open, or material may leak out.

The clamping force—stated in tons—required for a particular injection molding operation depends on the injection pressure. In turn, the injection pressure employed varies based on the viscosity of the material injected. For example, injection molding operations involving materials with higher viscosity—i.e., lower flow—necessitate the use of higher injection pressures to fill the mold. Therefore, in such operations, a higher clamping force is required to keep the mold closed.

When planning an injection molding project, it’s important to correctly identify how much clamping force is needed. Too little force can lead to mold leaks, while too much force can distort or damage the finished products and raise the cost of production. Some guidelines for determining the amount of clamping force required are as follows:

- Calculate the projected area (part length multiplied by part width)

- Multiply the calculated projected area by a factor of between 2 to 8 tons per square inch (the factor used depends on the viscosity of the injected material; for low viscosity materials use a lower number and for high viscosity materials use a higher number)

- Use the final product calculated plus an additional 10% as a precaution as the starting point for the amount of force the clamping unit should provide

- Add 10% for every inch over 1 inch in depth

- Double, triple, etc. clamping force for parts molded without shutoff land

How Injection Molding Tooling Works

Injection molding operations typically use two-plate molds—molds consisting of an injection mold component (the side where molten material is added) and ejector mold component (the side where a finished piece is ejected) held together by a clamping unit. The ejector mold has pins that break the vacuum seal between the workpiece and the mold to push the piece out of the tool.

Between the ejector mold and the injector mold is the cavity—i.e., the space into which molten material is injected. Some molds have multiple cavities to facilitate the production of several parts simultaneously. The molten material runs from the sprue bushing at the opening of the injection mold through the sprue and runners to the gate (i.e., entrance) of the cavity or cavities.

Finished injection molded products may have faint traces that indicate the gate’s position in the mold, such as the rough point at the bottom end of plastic cutlery. Additionally, they may have excess material at the area where the two molds halves meet, as the components do not line up perfectly and allow some material to flow between them during operations.

What to Consider Before Using Injection Molding

The injection molding process has many manufacturing benefits and limitations. Before choosing to use the process, consider the following to determine whether it is appropriate for your application:

- Part and mold design: the part design should accommodate the limitations of the injection molding process (i.e., have simple geometry and minimal parts required) and the mold should be designed and created with wall thickness, gate location, and other potential pain points in mind

- Upfront cost: the initial investment is much higher due to the part and mold design and prototyping stages

- Production quantity: the per-unit production cost is much lower for high volume orders

- Production and assembly operations: streamlining operations—including during molding and assembly—reduces lead times and production costs

Choose Valencia Plastics for Your Injection Molding Needs

For high-volume production orders, injection molding serves as a cost-effective solution for a wide range of products. If you need an injection molding partner, turn to the experts at Valencia Plastics.

At Valencia Plastics, we provide injection molding for micro to large and multi-component parts and products in a variety of different plastics. Our other molding capabilities include insert and over molding. For more information about our injection molding and other services, contact us today.