Blow Molding

Industry Experts

Valencia Plastics has pioneered the blow molding industry for over 20 years, manufacturing an impressive range of blow molded products. We are a full-service plastic molding facility offering start to finish blow molding services. Our state-of-the-art equipment and expert engineers help clients navigate from initial design to finished blow molded product with ease. We pride ourselves in providing the highest quality and best customer service in the blow molding industry.

What is Blow Molding?

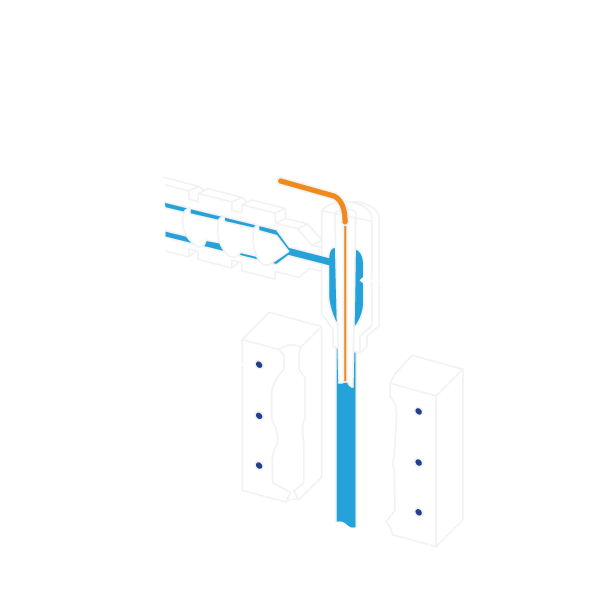

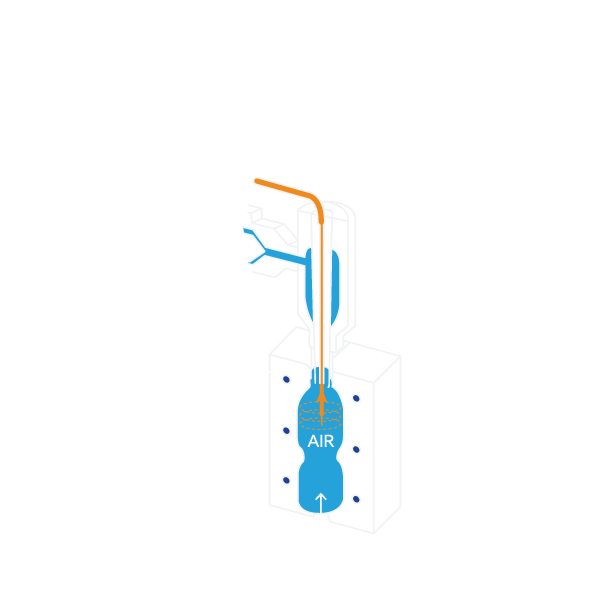

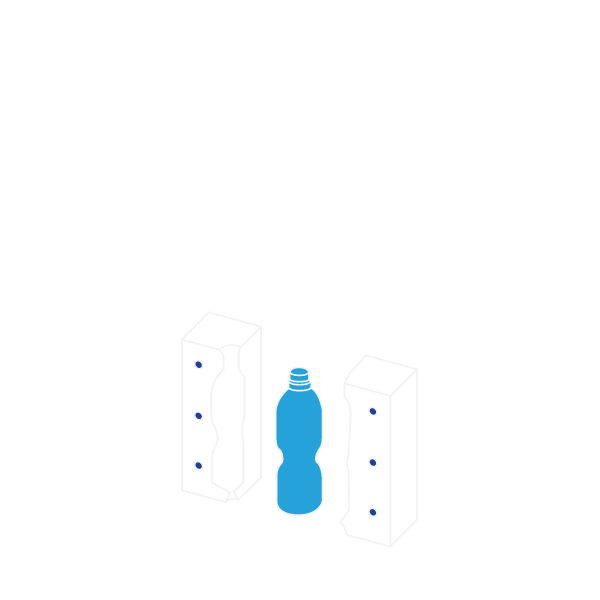

Blow molding is the process used to make hollow, plastic products such as containers or bottles. These plastic products or parts are created by extruding a tube of hot plastic, called a parison, into an open mold. Compressed air forces the plastic outward into the shape of the mold. Once it is properly molded, the plastic is cooled and hardened. Finally, the mold is opened and the completed, blow molded product is removed. The blow molding process is highly complex and requires the expertise of professional designers and engineers. Please contact us with your questions; our team is happy to help guide you through the process.

Blow Molding Capabilities

Materials We Work With

- Acrylonitrile Butadiene Styrene (ABS)

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Polypropylene (PE)

- Polystyrene

- Polyurethane

- Santoprene

- Kostrate

- K-Resin

Product Capabilities

- Large parts up to 5lb shot size

- Small parts 5 grams

- Multi-component parts (over molding and insert molding)

Mold Process Type

- Single cavity blow mold usually 70/75 aerospace aluminum.

- Multi cavity blow mold with beryllium pinch for longer tool life (mold life is in the millions of parts).

- We run air needle and blow pin blow molds.

- Molds that require inserts or over molded components are used.

Capabilities

Additional Capabilities

- Product assembly

- Custom colors

- Engineering

- Hot stamping

- In-mold labeling injection and blow molding

- Insert molding/over molding

- Mold making in house (Made In America)/with offshore option

- Product development (Inventor Assistance available)

- Screen printing/pad printing

- Secondary operations

- Sonic welding

- Tooling/mold design

- Turnkey solutions

- Warehousing/storage

Lead Times

- Quoted on job by job basis

- Production standard lead times are 2 weeks

- New tooling lead times are 4 to 6 weeks

- Expedited services available

Production Volume

- Custom specialty company

- High volume with storage capacity for on-time delivery

- Low volume

- Small production runs

File Formats

- Auto Cad (DWG)

- Drawing Exchange Format (DXF)

- Graphics Interchange Format (GIF)

- Initial Graphics Exchange Specification (IGES)

- Joint Photographic Experts Group (JPG/JPEG)

- Portable Document Format (PDF)

- Pro-E or Pro/Engineer (DRW/PRT)

- Solid Works (SLDPRT,SLDDRW,SLDDRT)

- Standard for the Exchange of Product Model Data (STEP)

What Our Clients Get

Often times, plastic molding facilities will outsource some of the work that goes into a blow molding project, like requiring clients to supply their own CAD specs for example. Making changes to molds or even getting ahold of a live, English-speaking engineer can be tough. We’re different at Valencia Plastics. Here, we offer all-in-one services and a friendly, knowledgeable team who can always answer your questions.

Proper Planning for Ideal Production

- Detailed planning during the beginning stages of your blow molding project is the best way to set yourself up for successful production.

- Discuss your project with one of our engineers. A well thought out design is critical to creating a finished product that meets your expectations and is economical to manufacture.

- A 3-D mock-up of your part will be created to help you visualize your product accurately before a physical mold is made.

- Realistic expectations and expert advice from our seasoned team will ensure the ease and efficiency of production.

Peace of Mind Choosing the Right Partner

- Finding the perfect manufacturer for your blow molded products can mean the difference between success and bankruptcy of your project.

- We utilize cutting-edge technology to ensure that our plastic molding processes are highly efficient, deadlines are always met, and our clients are treated as partners.

- We stand behind our products with intensive quality checks to ensure consistency and craftsmanship every time. We constantly strive to increase productivity while decreasing waste by using the latest in blow molding technology.

- Increasing your ROI and streamlining your experience are our top priorities here at Valencia Plastics.

Plastics We Work With

- ABS

- EVA

- Flexible PVC – TPU Blend

- K-Resin

- PETG

- Polycarbonate

- Polyethylene (HDPE, LDPE, LLDPE)

- Polypropylene

- Thermoplastic Elastomers

With these materials, we can achieve an array of functional properties, such as chemical resistance, biocompatibility, flexibility, stiffness, compressibility, memory, and FDA regulations.

Common Blow Molding Applications

- Antifreeze Bottles

- Any Type of Container with a Hollow Chamber

- Drums

- Fuel Tanks

- Garbage Cans

- One-piece Chair

- Pharmaceutical Bottles

- Polypropylene Bottles

- Plastics Parts for Telecommunications

- Water Bottles

Product Spotlight:

“The Rinse Hanger”

The Rinse Hanger is a complex blow molded part that was designed to easily and conveniently wash out the inside of your wetsuit. We designed and built the mold using ABS plastic because it is a very tough and durable resin with a UV repellant adaptive. This adaptive will help protect the blow molded tank from harmful UV rays for up to 5 years. The Rinse Hanger is an innovative way to wash the inside of your wetsuit after a fun day at the beach.

Blow Molding in the U.S.A.

- Conveniently located in Valencia, California, we are able to offer our clients unrivaled turnaround times and quick communication.

- We utilize the highest quality, most durable materials. Our steel molds last longer and can produce significantly more than typical aluminum molds used overseas.

- We are proud to be ISO certified, compliant with world-class specifications for quality and safety.

- Our unbeatable customer service will ensure a smooth and successful project. Manufacture your blow molded products here in the USA, with our expert engineers and unparalleled level of quality and service.

Industries We Serve:

Nutritional

Nutraceutical

Food

Pet Foods

Aerospace

Agricultural

Architectural

Construction

Consumer goods

Dental

Electrical

Health supplements

Marine

Automotive

Medical

Military

Oil Field Industry

Optical

Packaging

Pharmaceutical

Transportation

Featured Clients