When Strength and Durability are What Matters: Injection Molding is The Way To Go

Read moreWhen Strength and Durability are What Matters: Injection Molding is The Way To Go Look around, there’s plastic everywhere, and chances are that it had been injection molded. There are tons of reasons for this: cost, speed, versatility. But when strength and durability are what matters, then injection molding is the way to go. 1. Incredible Precision The

0

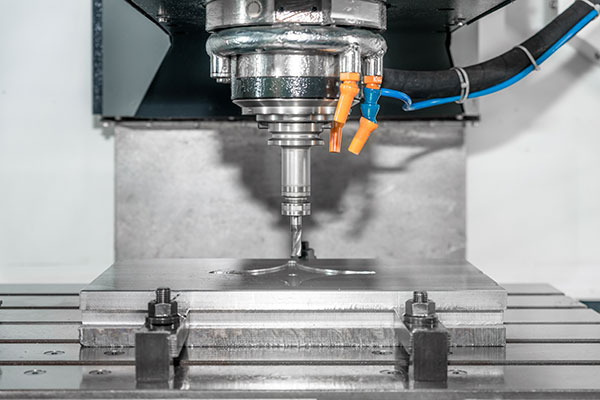

Consider the True Cost of Your Mold before Buying Cheap

In Mold Making onRead moreConsider the True Cost of Your Mold before Buying Cheap Wondering what a plastic injection mold will cost? It’s the most important question in the process, really. But, the answer isn’t as simple as it may seem. Just like buying a car, a new computer, or even a pair of shoes, the options and pricing vary based on the

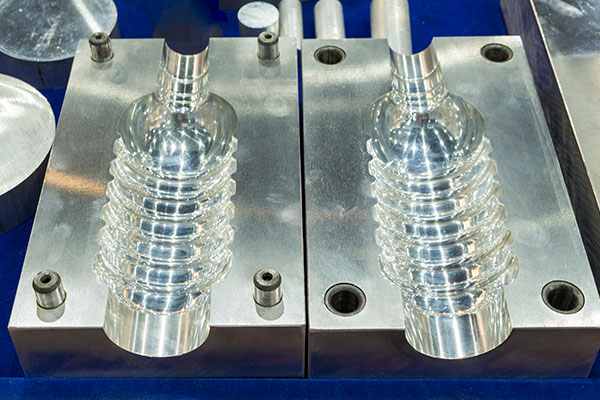

Choosing a Custom Plastic Bottle Manufacturer

In Blow Molding, Custom Blow Molding onRead moreChoosing a Custom Plastic Bottle Manufacturer When choosing a custom plastic bottle manufacturer, you need to consider several important factors. Here are some important options to explore before deciding who will produce your bottles. Quantity One decision is the number of bottles needed. Are you going into production with a proven product? If you already know how many

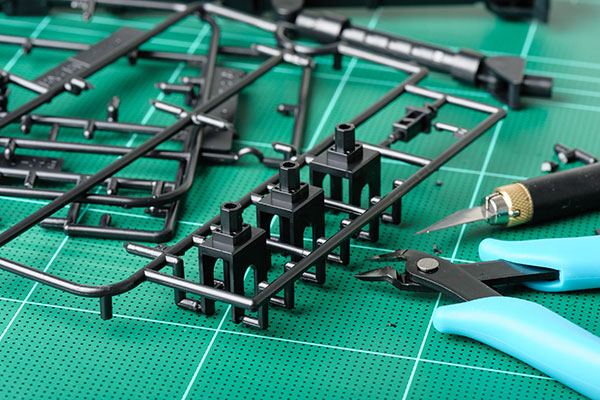

Steps for Successful Plastic Injection Molding

Read moreSteps for Successful Plastic Injection Molding Plastic injection molding is an effective process that is most successful with a little pre-planning. Before you jump straight to the design and production side of your new idea, take the time to consider all of the steps needed: Step 1: Determine the Moldability Before you can move forward, you have to determine

Three Mistakes Companies Often Make When Choosing An Injection Molding Company

Read moreThree Mistakes Companies Often Make When Choosing An Injection Molding Company Manufacturers use injection molding suppliers in a number of different industries. These companies provide critical components that decide the overall quality of the final product. Amazingly, firms often don’t ask simple questions that may decide the quality or reliability of their supplier. In fact, there are a few

Blow Molded Concrete Forms: On the Leading Edge of 21st Century Construction

In Blow Molding, Custom Blow Molding onRead moreBlow Molded Concrete Forms: On the Leading Edge of 21st Century Construction Blow molded technology has always been a leading contributor toward the advancement of the construction industry. Power tools, hand tools, heavy equipment, toolboxes and custom-fit cases all derive from blow-molded plastic manufacturing techniques. Now blow-molded plastic forms are poised to play a primary role in the actual

Why Injection Molding Is An Inventor’s Best Friend

Read moreWhy Injection Molding Is An Inventor’s Best Friend Whether you are an experienced inventor, or someone who has recently decided to make an idea come to life, you will want to begin by creating your product efficiently and accurately. With the help of Valencia Plastics, you will be able to create a prototype of your new invention and then use

Safety Considerations: Blow Molded Plastic Fuel Tanks vs Steel

In Blow Molding, Custom Blow Molding onRead moreSafety Considerations: Blow Molded Plastic Fuel Tanks vs Steel In 2016, 98% of vehicles in Europe and 75 % of vehicles in the US were fitted with plastic fuel tanks, according to a February 2016 report at Raybuck Auto Parts. EPA regulations pushing the industry to better fuel efficiency, as well as new safety considerations, motivated the trend favoring

Plastic Manufacturers and The Telecommunications Industry: A Partnership for Reliability

In Blow Molding, Custom Blow Molding onRead morePlastic Manufacturers and The Telecommunications Industry: A Partnership for Reliability The industrial term “telecommunications” conjures up images of complex printed circuit boards, internet routers, smart cell phones, and sophisticated computer chips, but the plastic components which are integral parts of these high-end electronic peripherals might hardly get an afterthought. But think about this. A typical TV remote contains 69

Why is Plastic Injection Molding Ideal for Military Use?

Read moreWhy is Plastic Injection Molding Ideal for Military Use? A frequently asked question is: “Why is plastic injection molding ideal for military use?” To answer this, let’s look at what plastic injection molding is and the benefits the military will see from using this type of process in the manufacture of equipment and products. Plastic is one of the

25611 Hercules Street, Valencia, CA 91355 | Office +1 (844) 574-2040